Engineering Standard 2.0

Precision in Motion

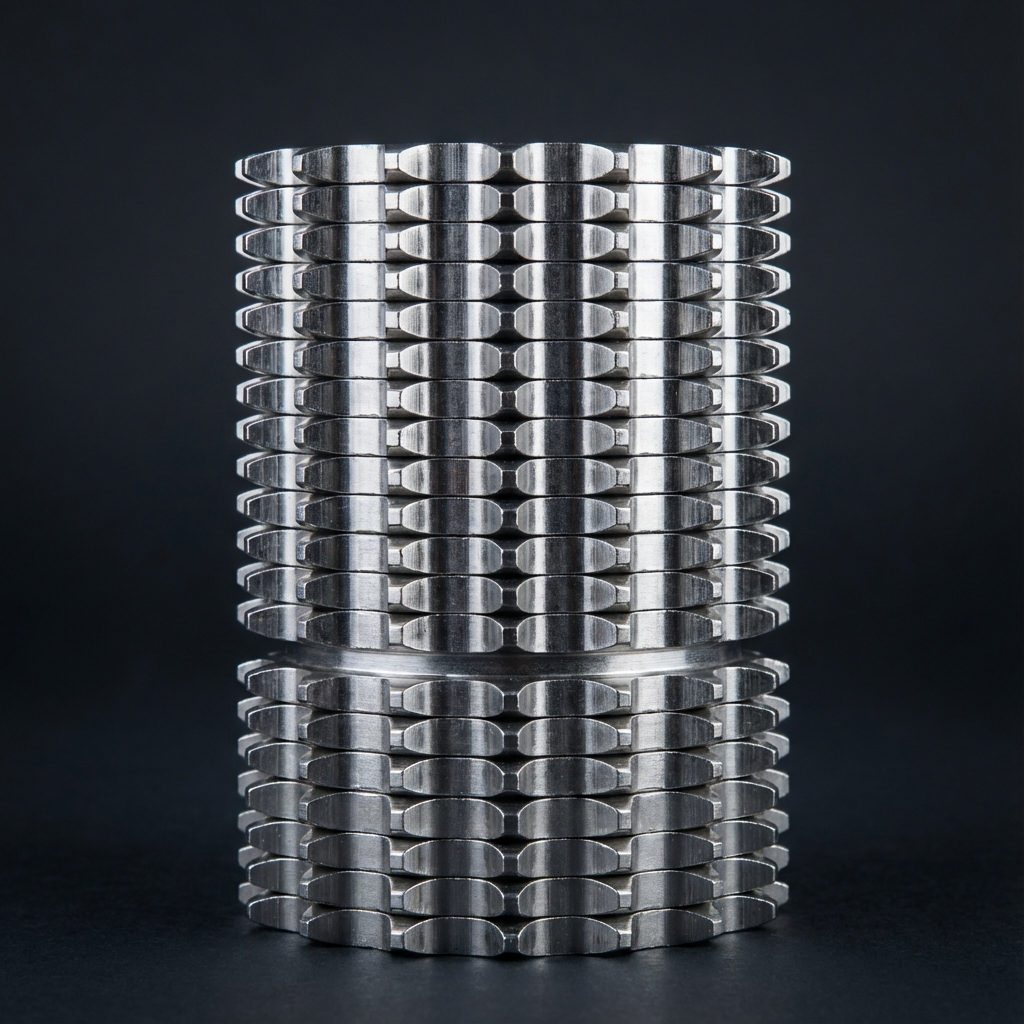

The Triple-Action Fine-Blanking process allows us to achieve 100% sheared surfaces without tearing.

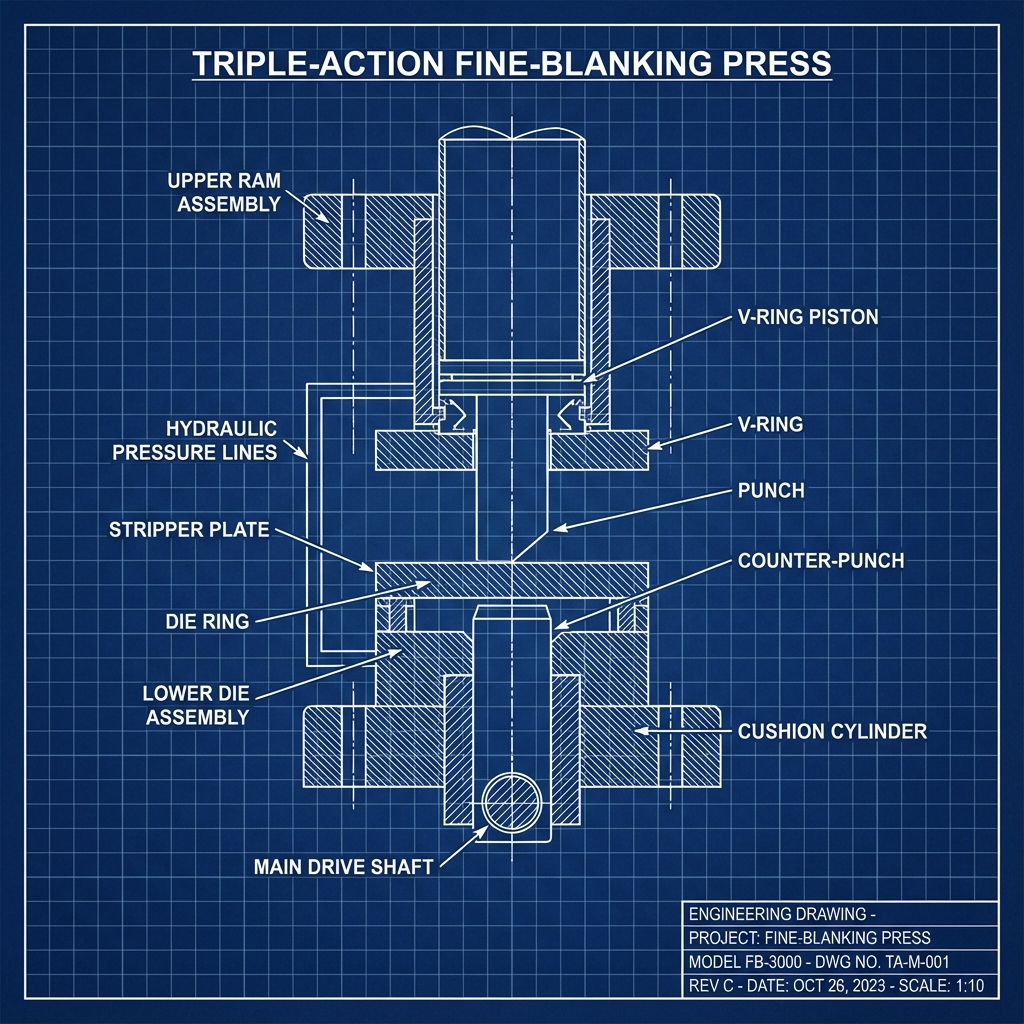

The Triple-Action Difference

FIG 1.2: SHEARED SURFACE FINISH

01

V-Ring Clamping

The unique V-Ring bites into the material before shearing begins, locking it in place to prevent material flow and tearing.

02

Controlled Shearing

Punch and counter-punch work simultaneously with precise clearance (0.5% of thickness), shearing the metal smoothly instead of breaking it.

03

Active Ejection

The part is ejected counter-pressure, ensuring flatness is maintained throughout the cycle.

The Process visualized

Premium Raw Material

High-Tensile Steel Coils

Precision Tooling

Triple-Action Die Sets

Consistency

Perfectly Flat Stacking

Quality Control

Micron-Level Tolerances

Engineering Specs

| PARAMETER | CONVENTIONAL STAMPING | FINE-BLANKING |

|---|---|---|

| Sheared Surface | 30% (Rough) | 100% (Smooth) |

| Dimensional Tolerance | ± 0.2 mm | ± 0.001 mm |

| Flatness | Needs Machining | Perfectly Flat |

| Secondary Process | Grinding/Shaving Reqd | Ready to Assemble |

| Steel Material | Standard Grade | High-Tensile Alloy |

*Data based on comparative analysis of 420 High Carbon Steel sprockets. Specifications may vary depending on material thickness and grade.